About inTEST Thermal Solutions

inTEST Thermal Solutions (iTS) specializes in the design and manufacture of precision temperature control systems. Our breadth of products and in-house engineering capabilities allow us to be a single-partner-solution for thermal test, process cooling, and cold storage applications. We are recognized globally for our expertise in precise temperature control and simulation of extreme thermal environments, from -185 to +500°C, with rapid transitions or long dwell times. The iTS family includes four product brands: Temptronic, Sigma Systems, Thermonics, and North Sciences. inTEST Thermal Solutions is a wholly owned subsidiary of inTEST Corp, Mount Laurel, New Jersey, USA.

With decades of product development, manufacturing and delivering over 100,000 controlled heating and cooling systems, we can address your specific requirements:

• Fast transitions (up to 50°C/sec)

• Cryogenic, compressor-based, solid-state cooling

• Temperature forcing, air & liquid environments

• Precise temperatures, High uniformity

• Extreme reliability

Thermal systems such as ThermoStream® forcing systems, thermal chambers, thermal platforms, and portable chillers provide end users and OEMs with highly reliable solutions. A worldwide network of local service providers and regional service centers ensure support that customers rely upon.

Combining the design and manufacturing operations of custom and standard products businesses, we provide the perfect blend of capabilities:

• Controls engineering

• Flexible manufacturing

After decades of solving thermal problems for development, lab, and production applications, we still get charged up about new temperature applications.

Talk to us about your thermal needs.

• Reduction of Customer Complaints

• Supplier Quality

• Continuous Improvement

Engineering

Our engineering expertise is second to none. From the thermodynamic, mechanical, electrical, and software disciplines to systems integration – all performed in-house – we ensure that our temperature systems will perform to your specifications. These capabilities give us design flexibility and rapid development turnaround time.

Mechanical designs, structural and fluid analysis are conducted using SolidWorks modeling and simulation tools. Our internally developed simulation process ensures that components are properly sized for the test, conditioning, or tuning application.

Combining modern engineering methods and materials, our team develops reliable, high-performance thermal systems – including custom designs with the smallest footprint possible. We are one of a few companies in the world to deliver autocascade refrigeration systems down to -100°C.

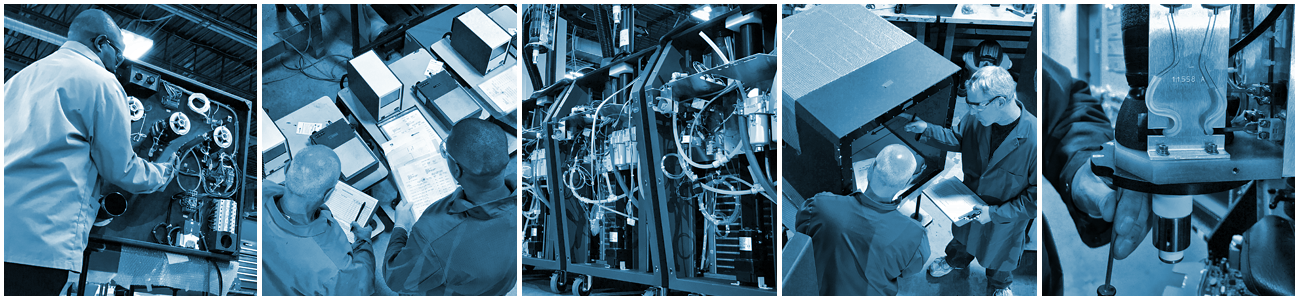

Manufacturing

In-house manufacturing capabilities provide a full range of metal fabrication, machining, welding, brazing, assembly and test to deliver on every aspect of the system's specification – build, test, site acceptance, delivery and performance.

Operating in concert with engineering, our production facility provides the flexibility to accommodate the design of standard and custom temperature systems.

We are an ISO 9001 registered company.

North Sciences, acquired in 2021 as Z-Sciences, designs and engineers laboratory equipment for biomedical, pharmaceutical, life sciences and healthcare. North Sciences provides a complete array of services and products designed to help every scientist gain a competitive advantage through stronger relationships, reduced costs, and optimized systems performance.

inTEST Thermal Solutions is part of the Environmental Technologies Division of inTEST Corporation (INTT, NYSE), a publicly-traded technology company headquartered in Mount Laurel, New Jersey, USA.