Easily Add Thermal Testing to your Industrial PCB Manufacturing Process

The Problem

Product reliability challenges over the specified thermal range of your printed circuit boards (PCBs).

The Solution

Thermal testing with a portable ThermoStream®.

Temperature Testing Solutions to Ensure Quality for PCB Manufacturers

The supply chain for electronic components has been in a state of uncertainty for several years. Obsolescence, long lead times, and high prices have led R&D teams to continuously source alternative components. Just because a sourced component has the same specification does not mean that it will work the same when it is integrated into a PCB. Thermal testing with a ThermoStream temperature system will ensure the reliability of your products over their operating temperature range.

Broad Temperature Ranges

-100 to +300°C

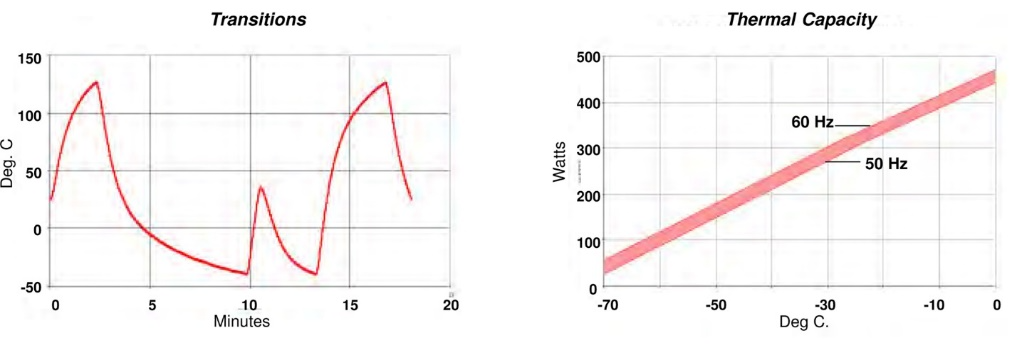

Rapid, Accurate Transitions

Up to 40°C/min., ±1.0°C

Standard & Custom Test Fixture Sizes & Shapes

Here's how the ThermoStream can add Commercial, Industrial, and MIL-STD temperature testing capabilities directly into a PCB production line

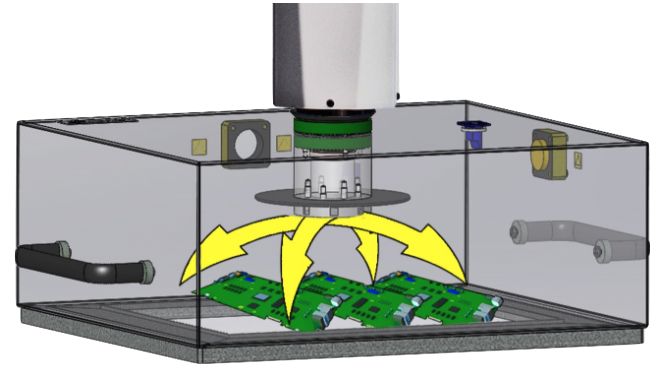

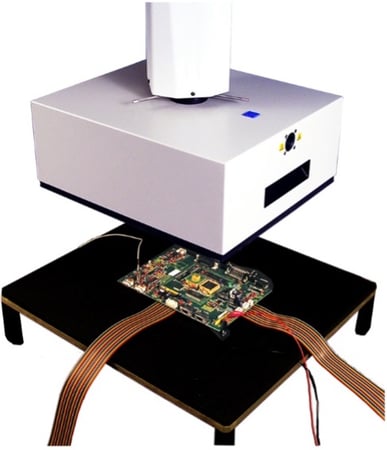

The ThermoStream is portable and can extend with an arm or hose to connect directly with in-line test enclosures to test your Units Under Test (UUTs) as they move through production. The ThermoStream allows manufacturers to bring the temperature test directly to their production line instead of removing PCBs from the line to place them in a test chamber or external thermal cycling system.

How the ThermoStream Works

The ThermoStream generates a high volume of clean, dry, air (18scfm) that is precisely controlled over a range of extreme temperatures (-80 to +300°C) to expose the UUTs to the desired test temperatures. The jet of hot and cold air has enough volume and thermal capacity to drive test enclosures to temperature rapidly, and accurately while testing single or multiple PCBs.

Advantages of Integrating a ThermoStream into a PCB Production Environment

- Easy Integration: The system is small (24”w x 28.5”d x 42.5”h), portable, and can easily be wheeled next to or in-line with the manufacturing process.

- Rapid, Precise, Temperature Control: -80 to +225°C range with up to 40°C per minute transition rates and ±0°C accuracy.

- Increased Efficiency: Reduces the need for separate testing stages, streamlining processes and improving throughput.

- Small Batch Testing: Enhances product reliability with early defect detection, faster feedback loop, and improved quality control.

- Cost Savings: By detecting defects and issues early, ThermoStream systems can help prevent costly recalls and warranty claims.

The Nimble, Cost-Effective Thermal Testing Solution

Small batch testing, in conjunction with ThermoStream systems, offers a nimble and cost-effective approach to achieving the quality and throughput goals of PCB manufacturers. As technology advances and the demand for high-quality PCBs grows, the integration of ThermoStream temperature test systems will continue to play a pivotal role in ensuring the success of electronics manufacturing endeavors.

Typical Performance