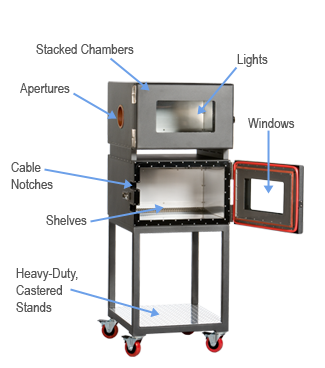

Thermal Chambers Configurations

Optimized for Lab or Production Test Throughput

Sigma Systems has a library of base models with the flexibility to select the configuration you need. Thermal chambers provide compressor-based single stage or cascade refrigeration, as well as LCO2 and LN2 cooling to meet demanding temperature needs, covering any range between -185 and 500°C.

Optimize thermal tests with any of these options:

• Chamber Sizes: Wide range of base models or custom size and shape

• DUT Access: Apertures, ports and notches

• Burn-in Chambers: Card cage mounting

• Door Configurations: Single, 2 door and top access

• Visibility: Interior lights and windows

• Chamber Stacking: Double floor space productivity

• Multiple Zones: 2, 3 or more zone chambers

• Fixturing: Shelves and insulators

• Configurable Controller: Remote communications, failsafe protection, multiple temperature probes, purging options

Apertures or Ports

Apertures or ports allow you to pass wiring and hoses through the wall of the chamber, while maintaining the internal temperatures.

The thermally resistant material of apertures and supplied foam plugs minimize heat transfer through the ports. Standard apertures are round and available in sizes from 1.25" to 4" I.D. (9.5 to 10.1 cm). Other size and shape apertures are also available.

Door Configurations

Configurable Doors allow chambers to be set up with multiple access doors. Doors can also accommodate slots for PCBs to maximize signal integrity under test. When you have devices that need setup (mounting, wiring etc.) on one side of the chamber and then have to access those devices from the other side, a two-door chamber is ideal.

Front- and Rear-door access provides access to test subjects on two sides. This is especially useful when connecting PCBs to a card cage on the opposing side of the chamber.

Slide-out doors can provide easy access for loading and unloading PCBs. Slide-out doors are often equipped with card cages.

Chest style chambers: For applications that need frequent access to the chamber when at cold temperatures, a chest style chamber reduces loss when the door is open

Visibility

Interior lights make loading chambers, especially deep models, much easier. Lights are also the perfect companion to a window option, providing excellent visibility without having to open the chamber door. You can control interior lights manually, with a door operated switch, or by program control using the TS Controller.

Windows allow observation of the test in progress. Multi-plate insulated windows remain clear during test and resist temperature transfer from the interior to the exterior. Window size will vary with the actual size of the chamber door. The "door trim' around the window will remain about the same for all but the smallest chambers.

Stacked Chambers

Custom chamber size and shape, beyond standard building block designs, can be specified to fit your DUT. We specialize in critical applications where a standard thermal chamber is not compatible with your requirements for size, shape, temperature, or throughput.

Stacked Chambers provide more density of test volume than two side-by-side chambers. Stacking is a common approach for saving space on the production or lab floor.

Fixturing

Shelf insulators provide a non-conductive work surface for your chamber. They will withstand temperatures from -65 to +120°C. Insulators rest on top of the standard stainless steel shelves. Holes allow conditioned air to flow around your DUTs. They are available for all chambers smaller than 25 sq in. (63.5 cm)

Chambers with Thermal Plates use the thermal platforms as active heat sinks for the device while the chamber simulates the hostile environment.

Chamber shelves (standard option) are rated for 200 lbs (91 kg) distributed load.

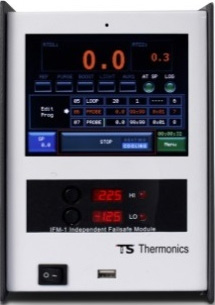

Controls, Communications, and Failsafes

The Chamber controller (TS Series Controller) provides touch-screen operation and real-time graphing, plus two types of control - system and DUT control. The unique DUT Control mode provides a faster method to get your device to temperature.

CE approved, the controller logs and displays diagnostics such as valve counts, ambient temp, and equipment runtimes. Multiple communications protocols are included. It also has an option for an independent fail safe to protect the DUT from thermal damage. Chambers equipped with a C3 and C4 controllers can be upgraded with a fully compatible TSR Controller.

Dry Nitrogen purge systems eliminate moisture and/or oxygen from the test environment. Even Nitrogen cooled chambers can benefit from a dry Nitrogen purge as the purge can be used even while the chamber is heating. Control the purge manually, with a door switch, or by controller control. Purge systems are available for any chamber.

Customers can install a gas purge system using components or a kit from Sigma Systems or be included on the front panel of a TS Controllers when ordered.