LN2-Cooled Cryogenic Chillers

Portable Process Chillers for Ultra-Low Temperatures and Rapid Cooling

-100°C Ultra-Low Temperature

Cooling Capacity up to 20kW at -90°C

Small Footprint (inches)

64H x 22W x 28D

Thermonics Cryo Chillers use liquefied cryogens (LN2 to cool heat transfer fluids with a proprietary cooling technology, delivering low and ultra-low temperatures and rapid transitions rates to a test device or process.

Cryo Chillers are compact, portable systems ideal for both ultra-high and variable capacity cooling applications where supply of LN2 or LCO2 is automatically adjusted by the chiller’s control system to meet the specified cooling requirements.

Cryo chillers are used in an assortment of industrial and commercial applications including: Defense, Aerospace, Chemical, Semiconductor, Pharmaceutical, Automotive, and Medical. In the right applications, a cryo chiller is a simplified and more cost effective cooling solution delivering a high ratio of capacity to system

Typical LN2-Cooled Chiller Performance

| Temperature Range | Stability | Cooling Capacity (kW) | Pump Capacity (GPM) | Options |

| -100 to +200°C | ±0.5°C | Up to 20 kW at -90°C | Up to 10 GPM | Variable Frequency Drive (VFD), Programmable Fluid Pressure and Fluid Flow Rates, Auto fill, Auto drain |

Pros and Cons of an LN2-Cooled Chiller

Pros:

• Highest capacity cooling, up to 20 kW cooling power

• Cools fluid tanks or "tankless" in-line fluid flow

• Variable, on-demand cooling when needed

• Extremely fast temperature transition rates

• Smaller footprint than compressor-based chillers

• Less expensive purchase price than compressor-bases chillers

• Proprietary technology prevents freezing of heat transfer fluids

Cons:

• LN2 consumption adds long term costs

• GN2 exhaust requires ventilation

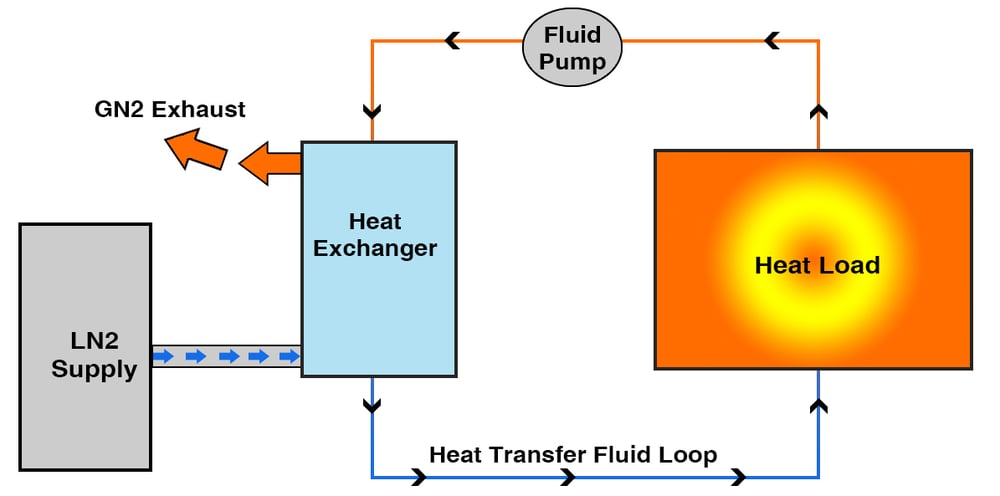

How An LN2-Cooled Chiller Works

Liquid nitrogen (LN2) is supplied to a heat exchanger where it cools the heat transfer fluid. The heat transfer fluid is continuously circulated in a loop between the heat exchanger and the heat load. Heat from the heat load is continuously transferred to the heat exchanger where it is expelled with the gaseous nitrogen (GN2) exhaust.